AIM Intelligent Machines

About AIM Intelligent Machines

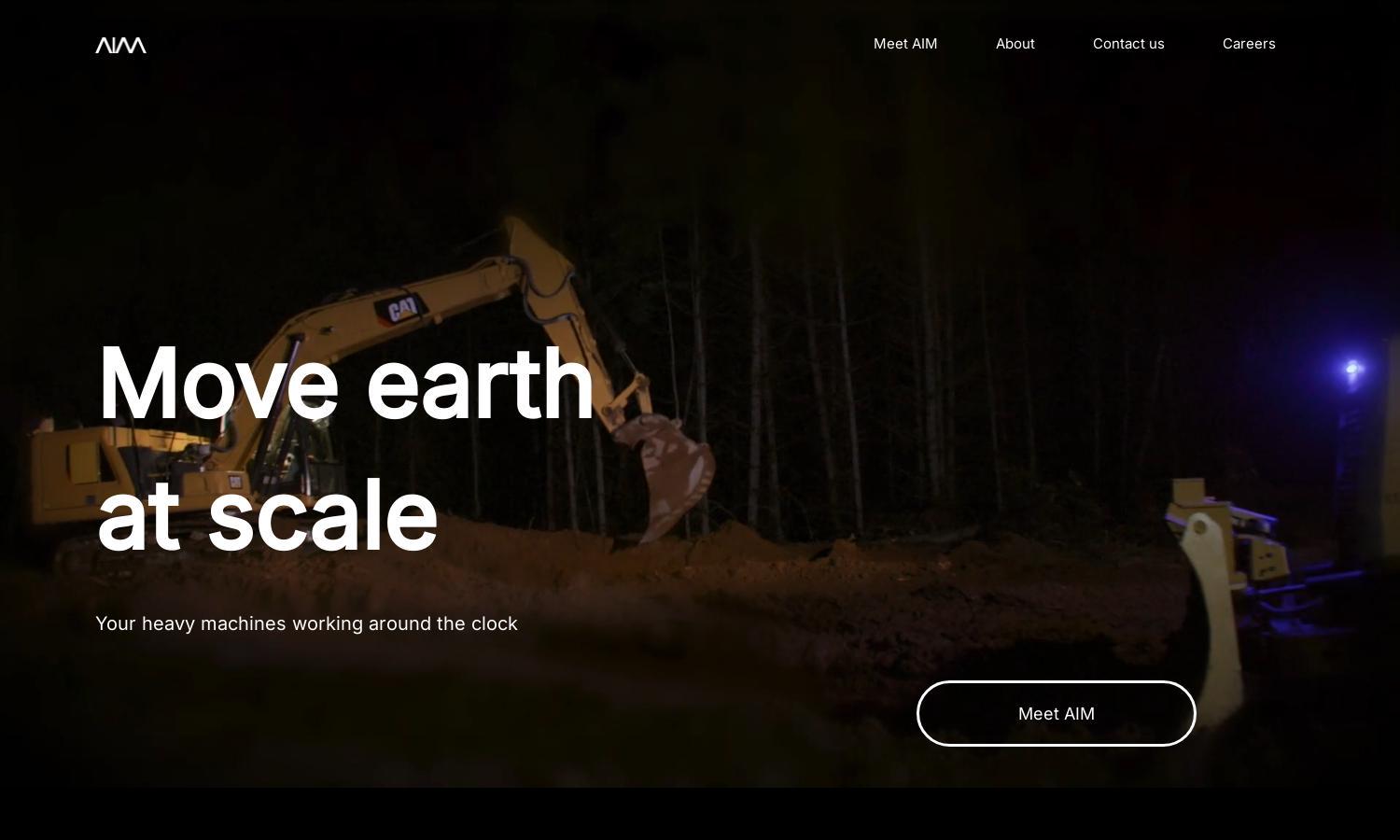

AIM Intelligent Machines is dedicated to enhancing civilization's capabilities through heavy machinery automation. With a revolutionary retrofit system, AIM allows earthmoving machines to operate without an operator, ensuring maximum safety and productivity. By replacing hazardous manual tasks, AIM empowers workers to focus on advanced operations, analytics, and site planning.

AIM Intelligent Machines does not specify pricing plans. Interested users can book a consultation to understand customized solutions tailored for their operations. Upgrading offers enhanced safety and efficiency. Clients benefit through improved machine performance and seamless integration, reinforcing AIM's commitment to advancing autonomous technology and operational excellence.

AIM Intelligent Machines provides an intuitive user interface designed for effortless navigation. The platform seamlessly integrates cutting-edge automation features, allowing users to easily monitor and manage machinery. With its user-centric design, AIM enhances the overall experience, ensuring users can maximize the benefits of their autonomous heavy equipment.

How AIM Intelligent Machines works

Users engage with AIM Intelligent Machines by first consulting with the team to assess their existing equipment. After onboarding, the AIM system retrofits the machinery to enable autonomous operation while allowing manual controls. Users then navigate a straightforward dashboard, which provides real-time monitoring, analytics, and safety checks, ensuring ease of use and optimized performance.

Key Features for AIM Intelligent Machines

Retrofit System

The retrofit system of AIM Intelligent Machines stands out for transforming existing heavy equipment into fully autonomous entities. This innovative feature ensures seamless integration without the need for new machinery, empowering businesses to maintain operational efficiency while enhancing safety and productivity.

360-Degree Safety

AIM Intelligent Machines' 360-degree safety feature provides comprehensive protection for ground staff. By utilizing advanced sensors and safety protocols, this system ensures no one is exposed to hazardous environments, making autonomous operations both safe and efficient, thus maximizing productivity on job sites.

Expert Engineering Team

AIM Intelligent Machines boasts an expert engineering team, drawing on experience from industry-leading organizations like Google and Tesla. Their deep expertise in robotics and AI ensures that the technology is cutting-edge, providing robust, safe, and effective solutions for autonomous heavy machinery operations.